What are the capabilities of a die cutting machine?

The die can be customized to add specific details and features to the finished part based on the end application. The capabilities of a die cutting machine include:

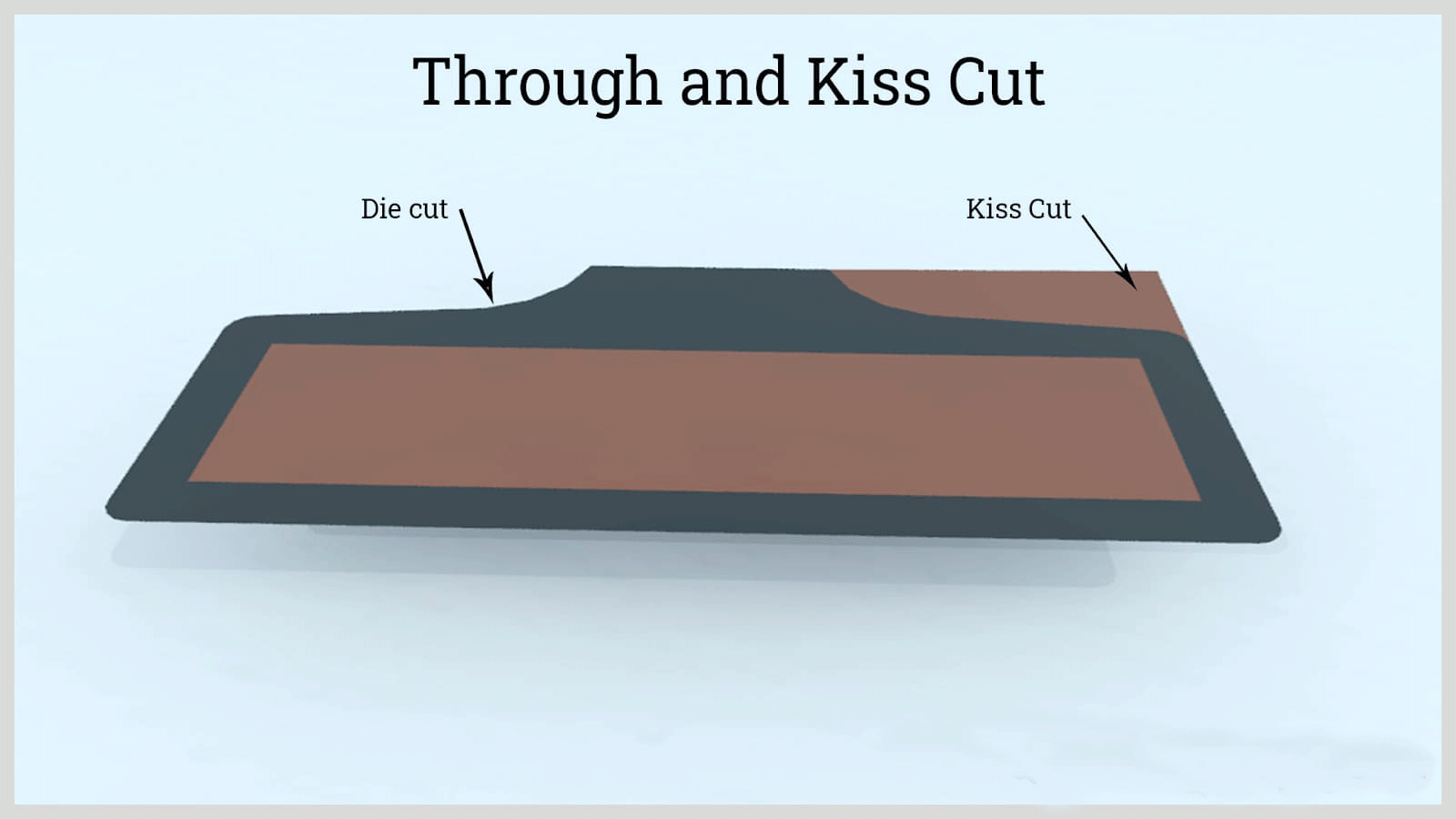

Through Cutting

Through cutting is a die cutting technique where the sharp edge of the die extends through the entire thickness of the material, resulting in complete separation of the part. In multi-layered materials, this means cutting through the face, adhesive, and backing layers. Dies used for through cutting can also be designed to score, crease, and cut in a single stroke. The blade for through cutting is longer and thinner than those used for scoring or creasing, enabling it to cut through any depth or thickness of the material.

Kiss Cutting

Kiss cutting, on the other hand, is a type of cut in which the edge of the die partially cuts through the material‘s thickness and only forms the perimeter of the finished part. For multi-layered materials, only the face and adhesive layer are cut. The part is not fully separated from the stock material but can be easily detached on the kiss cut.

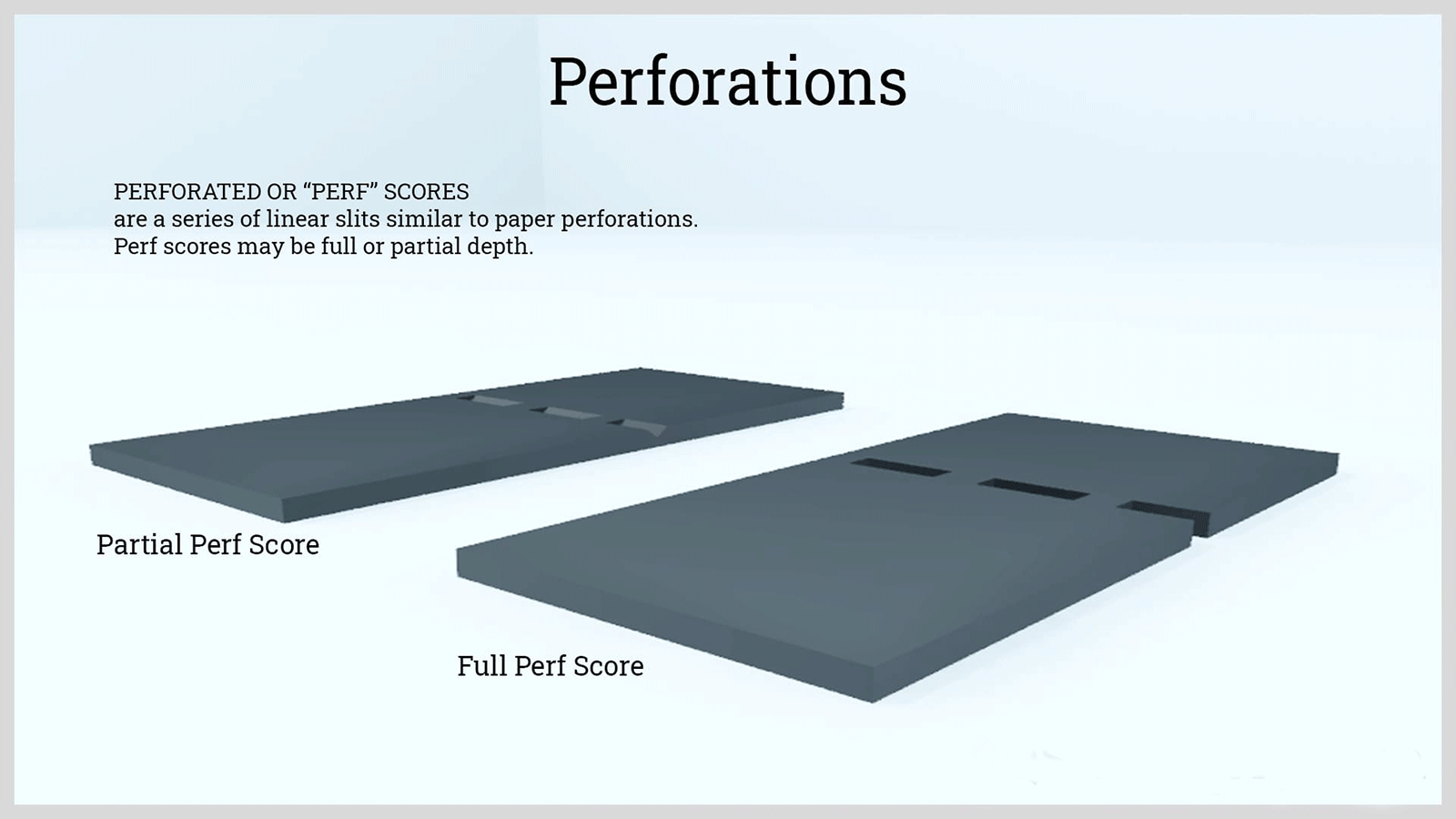

Perforating

Perforating, also known as piercing or coining, is a die cutting technique that creates a series of small, punched holes arranged in a line across the material. This process uses pressurized force to produce these holes. The spacing between the holes affects how easily the material can be torn along the perforated line. While perforating does not fully separate the part from the stock material, it allows for easy detachment along the perforated line.

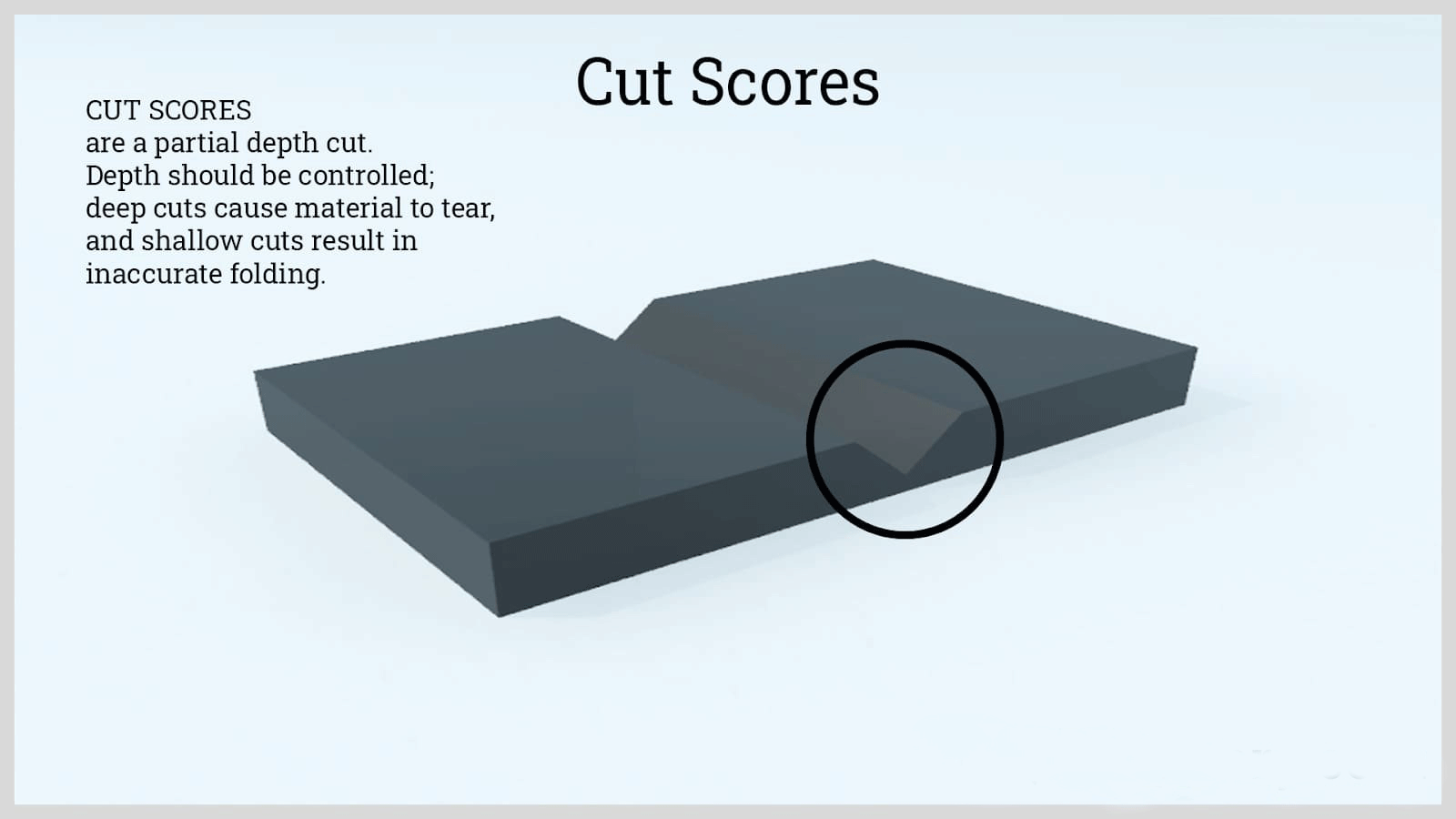

Cut Scoring

In cut scoring, the die creates a partial cut or a small indent along a stress point on the material without cutting through its entire thickness. This technique only slices less than half of the material's depth, facilitating easier tearing. The scoring tool's blade is shorter and thicker compared to a full cut tool.

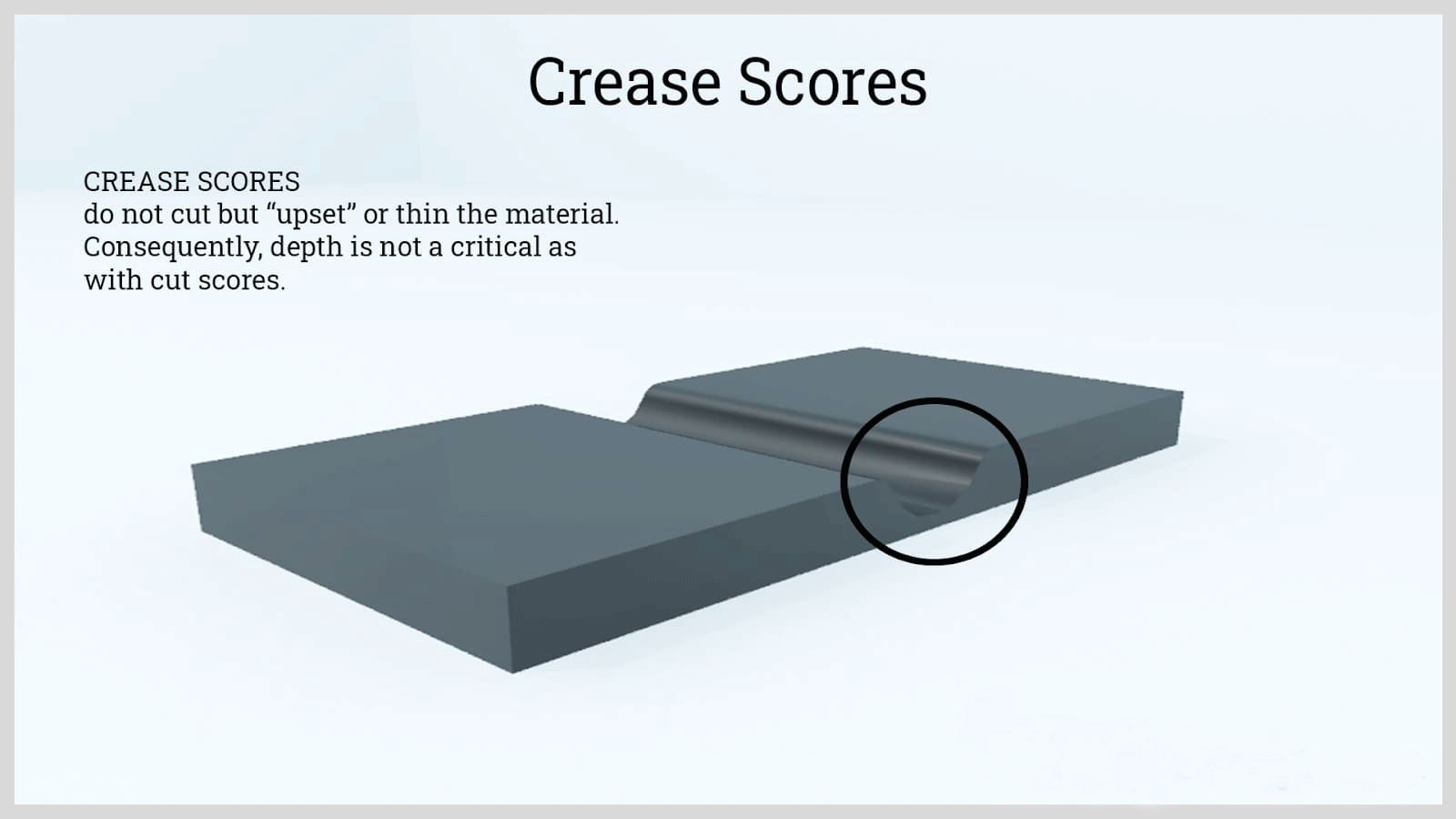

Crease Scoring

Creasing involves creating indents aligned along a line by applying pressure to reduce the material's thickness on one or both sides. Unlike cutting or perforating, creasing does not create a pierced perimeter, and the depth is shallower than that of cut scoring. This process helps in making even folds, facilitating the creation of three-dimensional profiles. The resulting folds are more flexible and precise, enhancing the material's ability to form distinct shapes.

Broaching

Broaching uses dies with a combination of multiple teeth that pierces together on a single stroke to cut extremely thick or rigid material. Other die cutting machine capabilities utilized to decorate the finished part are embossing, engraving, forming, and drawing.

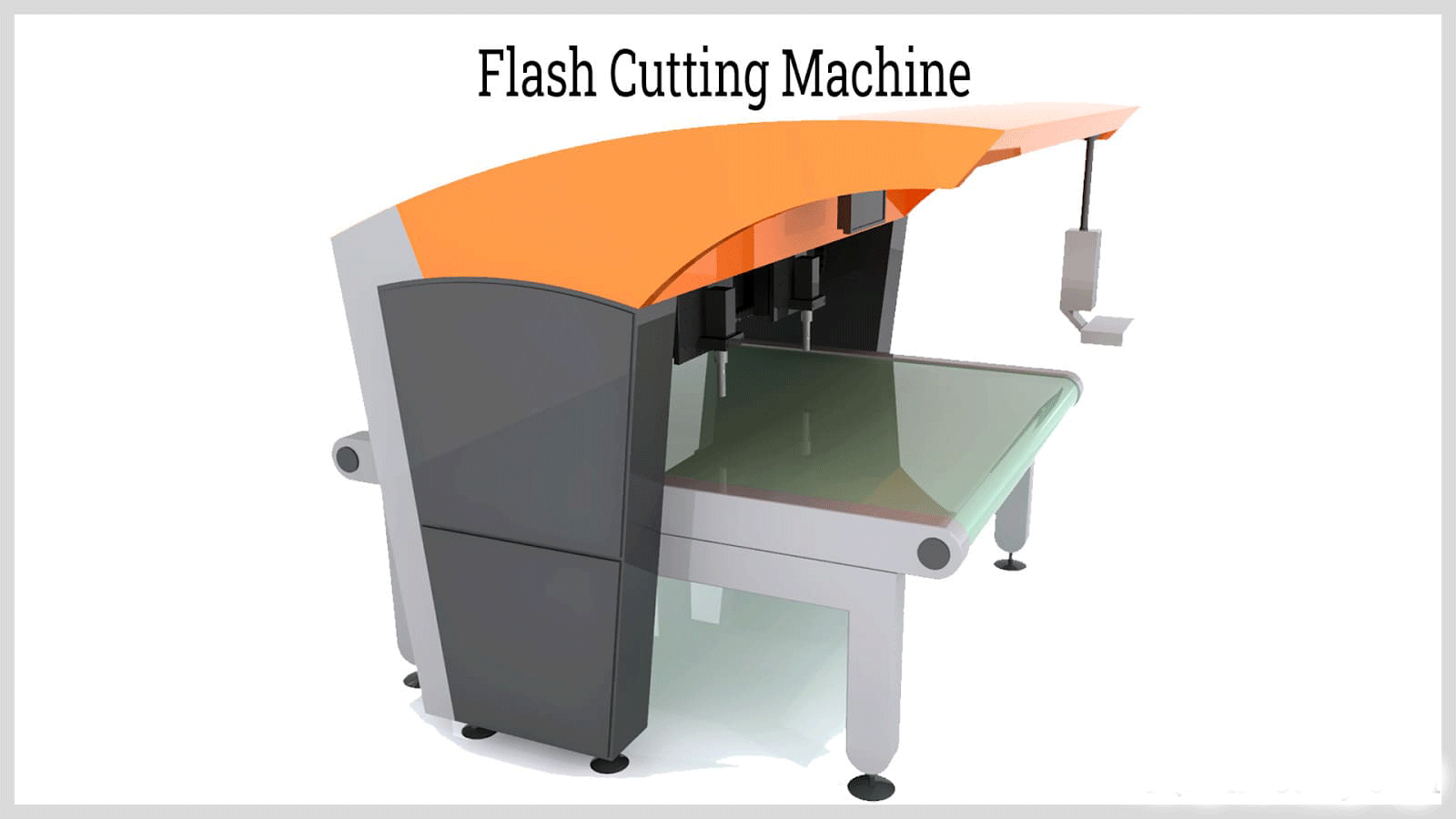

Flash Cutting

The flash cutting process uses an oscillating knife instead of a die to cut materials at varying depths. This technique allows for a broad range of cuts, including engraving, milling, plotting, kiss cutting, and creasing. The cutting machine holds the blade steady, ensuring accurate and clean cuts. Ideal for rapid prototyping and producing aesthetically perfect parts, flash cutting is a CNC-based process where cutting parameters are programmed into the CNC machine. It eliminates the need for tooling, enabling faster project completion and quicker market readiness.

-

4th Floor,No.428 Wenzhou Avenue,Puzhou Street,Longwan,Wenzhou,China,

-

+86-577-66688057

+86-18058846873 -

Copyright © 2019 CHINA . Wenzhou Andy Printing Machine Factory and Suppliers.