- Home

- About Us

- Products

- Services

- News

- Contact

What are rotary die cutting and semi-rotary die cutting?

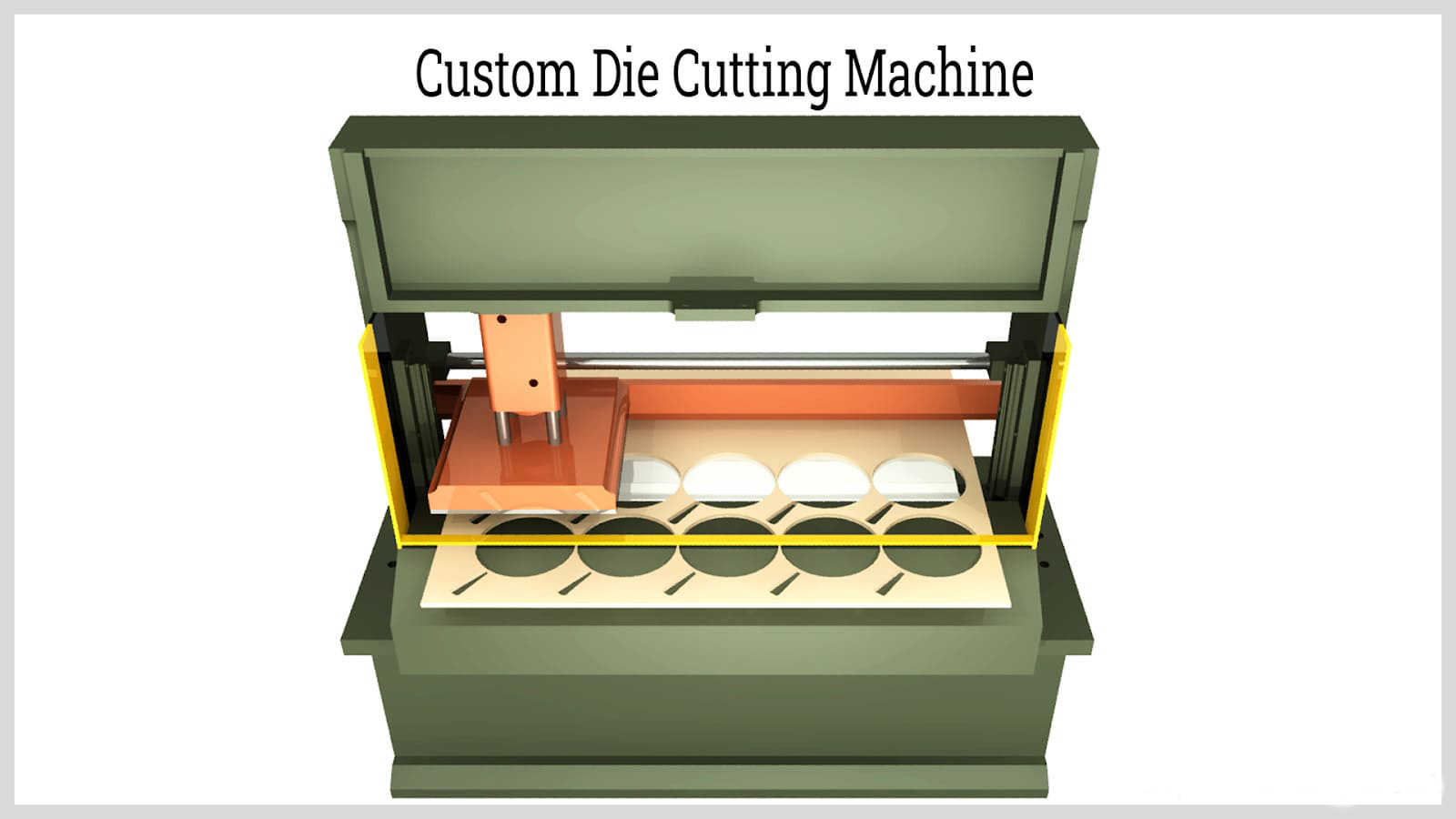

Rotary die cutting machines operate continuously at lower cutting pressures and constant speeds, making them well-suited for being positioned directly downstream from a previous process. These machines are ideal for producing simpler and lighter parts, offering versatility for various materials and a quicker turnaround than flatbed die cutters.

The stock material, or web, in sheet or roll form, moves through the cutting assembly. This assembly consists of a rotating cylindrical die mounted on a rotary press and an anvil cylinder pressing against the rotary press. As the web passes between these rotating cylinders, it is compressed, allowing the sharp edges of the die to cut through the material.

A rotary die cutting machine can perform both full and partial cutting. While the fundamental steps are similar to those in flatbed cutting machines, the mechanism of the cutting assembly differs.

There are two types of rotary dies, chosen based on the material properties and economic considerations.

Flexible Rotary Die

Flexible rotary dies are crafted from thin steel sheets with engraved patterns that form the cutting edges, wrapped around a magnetic cylinder. They are suited for low pressure and shallow or partial cuts. The thin cutting sheet can be replaced according to the specific part to be cut, and the magnetic cylinder can accommodate various flexible dies.

These dies are cost-effective and easier to manufacture, with minimal downtime during replacement. However, they are less durable compared to solid dies.

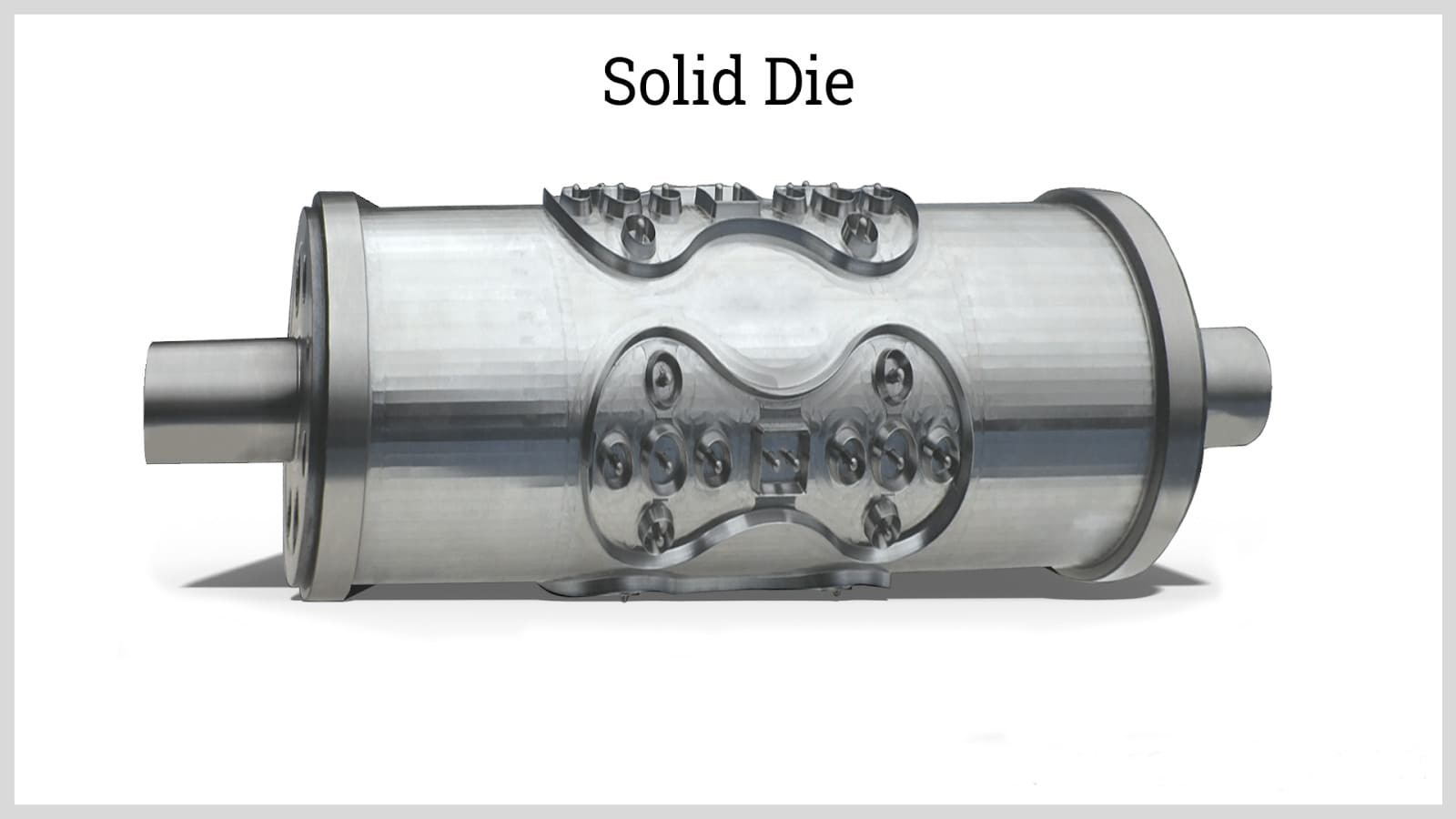

Solid Die

A solid die features engraved, abrasive patterns directly on the rotating cylinder. Designed for higher pressure applications, it can handle deeper cuts on thicker and multi-layered materials due to its ability to exert greater forces. Solid dies can be sharpened when worn out, offering greater durability and flexibility. However, they come with higher initial and maintenance costs.

When operating a rotary die cutting machine, several operating and material conditions must be considered:

The tangential speed of the rotating cylinders and the speed of the web must be the same. This ensures proper placement of the material between the two cylinders, resulting in precise and uniform cuts through the entire length.

The clearance between the rotary press and anvil cylinder must be optimized according to the thickness and compressibility of the stock material. If the clearance is too narrow, higher cutting pressure will be applied which may cause fatigue in the machine components. On the other hand, if the clearance is too large, the cutting pressure is not sufficient to cut the sheet properly. Large clearances are suitable only for partial cutting.

The rotary die to be selected must have a blade width and angle that is optimal for the material to be processed. Thicker and more rigid materials require a wider and steeper blade.

Semi-rotary Die Cutting

This type of die cutting machine is similar to a fully rotary die cutter but utilizes only one cylinder containing the die for cutting. The semi-rotary die cutting equipment is programmed so that the cylinder moves in a single direction while the web moves back and forth. This combination of cylinder and web movement allows for multiple cuts, eliminating the need for an additional cylinder.

Semi-rotary die cutting machines are generally less expensive than fully rotary and flatbed die cutters. However, they are limited to low-pressure applications.

While industrial-scale die cutting machines have been discussed, the following equipment is used for creating simpler parts with a relatively low production rate, making them suitable for small-scale applications:

Manual Die Cutter

Manual die cutters operate by pushing a crank lever, which presses the steel dies onto the substrate to cut out the finished part. This method is ideal for soft materials like paper.

Manual die cutting is particularly suitable for producing auxiliary items. This equipment is compact and portable, commonly used in homes, offices, and craft spaces.

Digital Die Cutter

A digital die cutter is a versatile machine controlled by computer software or cartridges. Unlike traditional die cutters, it uses sharp blades instead of steel dies and is powered by electricity. Digital die cutting machines, like manual ones, are suitable for indoor installation.

-

4th Floor,No.428 Wenzhou Avenue,Puzhou Street,Longwan,Wenzhou,China,

-

+86-577-66688057

+86-18058846873 -

Copyright © 2019 CHINA . Wenzhou Andy Printing Machine Factory and Suppliers.