Features:

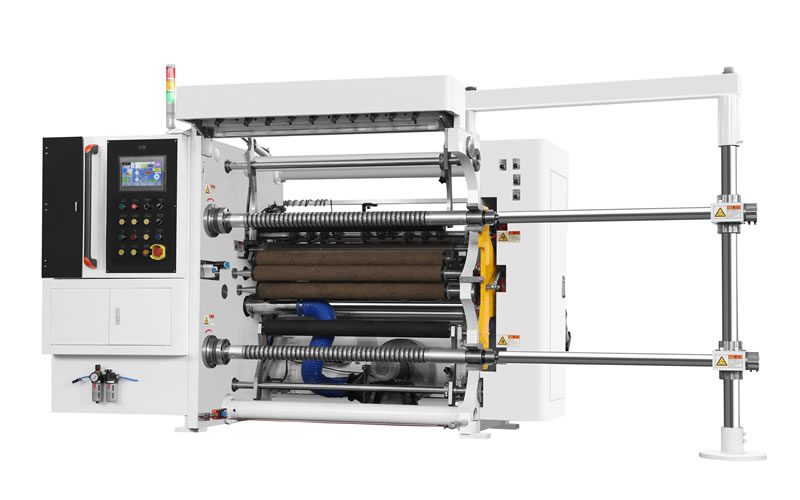

1. The whole machine adopts advanced PLC control system and friendly HMI. The machine parameters and operating

status are always visible. The whole production process is fully automatic without manual operation.

2. Taiwan Taibang frequency conversion motor and Delta frequency conversion as well as high level phasical

components built in.

3. Adopt pneumatic (air-expanding shaft) upper base paper system, and a separate air cylinder controls the locking

shaft.

4. All the conveying rollers have been dynamically and statically balanced, all the processed iron parts have been

hard soldered, and the aluminum parts have been anodized. Each machined part has a unique part number.

5. The machine is equipped with a red line marking system, and the end of the paper roll is printed with a red line

mark (using the printing principle to transfer ink). The cordon width is 5mm.

6. The machine adopts circular knife cutting and automatic waste suction system. Equipped with a 2.2KW independent

edge suction device (all the paper edges are put into a special waste collection box, and the shredded paper edge

cannot be seen next to the machine, making the workshop more tidy.

7. Start-up: automatic knife insertion, fast winding by air blowing.

8. Constant tension control, the machine runs stably.

9. Using automatic counting of meters or diameters, when the set value is reached, the machine will automatically

run the next program (don't worry about inaccurate product meters or diameters, the deviation is within 3cm).

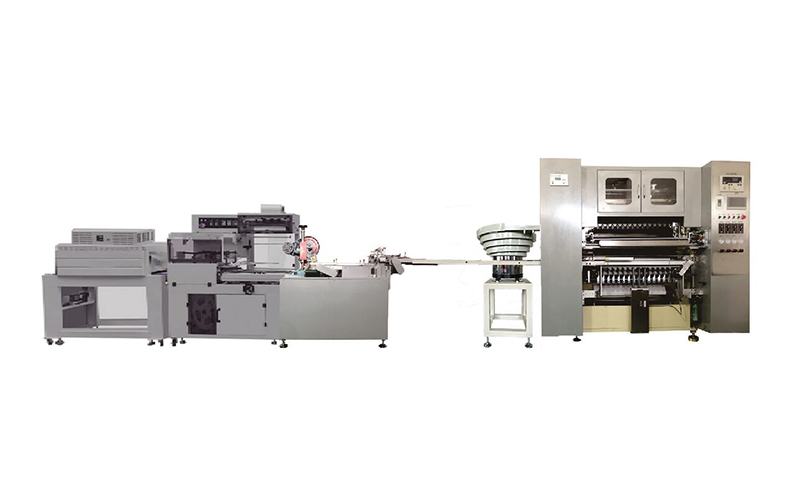

10. The slitting machine is equipped with automatic cutting and automatic water glue sealing stations. The general

functions of the main machine are: automatic cutting, automatic paper core loading, automatic sealing, automatic

delivery out, automatic conveyor to the next process.

11. Automatic deviation correction, adopting Taiwan Laisen deviation correction system.

12. Automatic paper core feeding system.

13. Equipped with end-of-roll detection and joint detection,to realize automatic shutdown of material run up.

14. The finished product conveying line is equipped with an automatic splitting and knocking device, and it is sent

to the packaging machine for packaging

15. Conveying device with core arrangement, diameter: max700mm, speed: 130pcs/min.

The main technical

parameters:

Web W idth

400-870 mm

Maximum U nwind D ia .

1100 mm

Maximum Re wind D ia .

8 0mm

Cutting width

30-870 mm

Material Thickness Range

45-80 gsm

Max S peed

200 m/min

Cutting accuracy

±0. 3 mm

Rewinding mandrel diameter

13~26mm

Rewinding diameter

30-80mm

Uniformity of winding

section

±0.5mm

Air Supply

> 0.75pa

P ower Supply

7KW

Voltage

380V 6 0HZ ( 50HZ )

M achine weight

3000kg

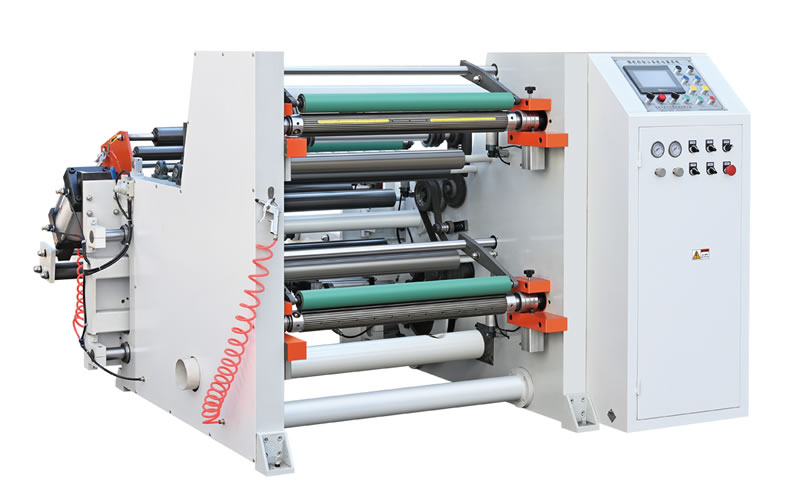

Dimensions of the slitter

L2500*W2000*H1850 mm

Details Configuration:

Items

Manufacturer/Brand

Main Controller

Panasonic

Monitor

Taiwan WEINVIEW

Air Cylinder

AirTAC/xingchen

The electromagnetic valve

NKA Taiwan

Trachea

AirTAC

Inverter

Delta

Relay

Omron

Switch

Chint

Magnetic Particle Tensioner

Taiwan Leisen

M otor

GPG ,

Taiwan

screw

12.9 level

M ain wall

panel

Using 45# steel, precision mold

knife holder

fine grinding, electroplating

knife set

Fine grinding, blackening/plating

transformer

Imported from Taiwan

sensor head

imported from Korea

Guarantee:

Within one year guarantee from installation date. This machine will be whole packed and loaded with whole machine

when it arrive customer's side.The seller will bear the cost for defective parts arisen by quality and courier the

parts.meanwhile the freight cost should be paid by the buyer's side. Additionally, if the defective parts are

arisen by improper use of buyer's side, the seller will not supply them for free.Following photos and

videos(for reference only) .

VIDEO

Feedback

Welcome to our website. If you have any requests or suggestions,please feel free to email us at [email protected]