1. The main motor adopts imported inverter to govern a stepless speed adjustment.

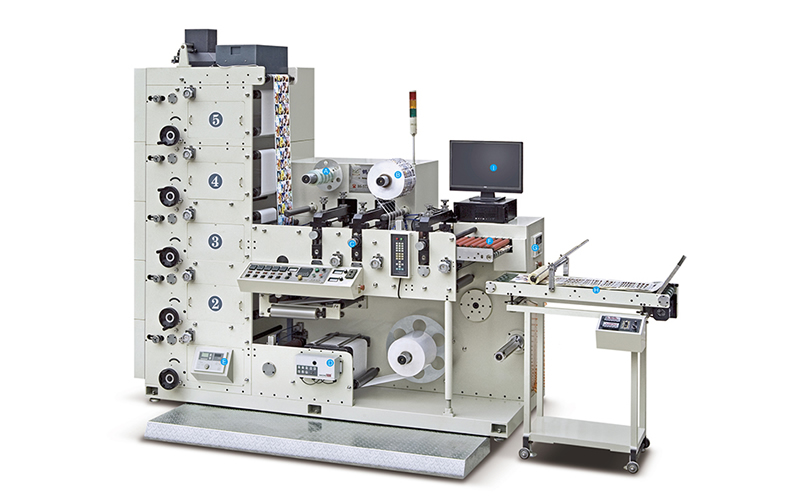

2. Feeding and rewinding are controlled through magnetic particle brake and clutch (Janpanese Mitsubishi auto tension controller).

3. Unwinder system is controlled by edge guide sensor.

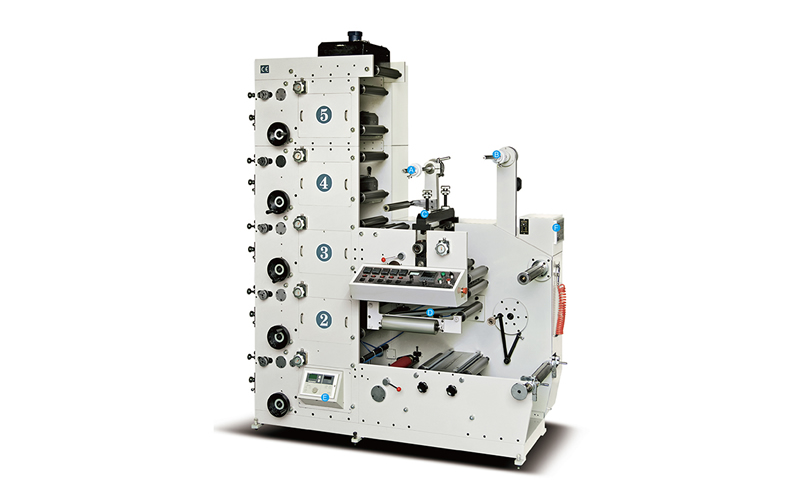

4. Adopt ceramic anilox roller which offers durability, wear resistance and corrosion resistance, also is more efficient on production by reducing the times of changing rollers.

5. The printing units are all equipped with a group of infrared dryers respectively.

6. Each IR dryer device of printing unit is interchangeable to UV dryer.

7. Unwinder and rewinder adopt are core holder.

8. The printing unit can register in 360 degrees. Each printing unit can be independently geared and loosen to have rest of units continue to printing.

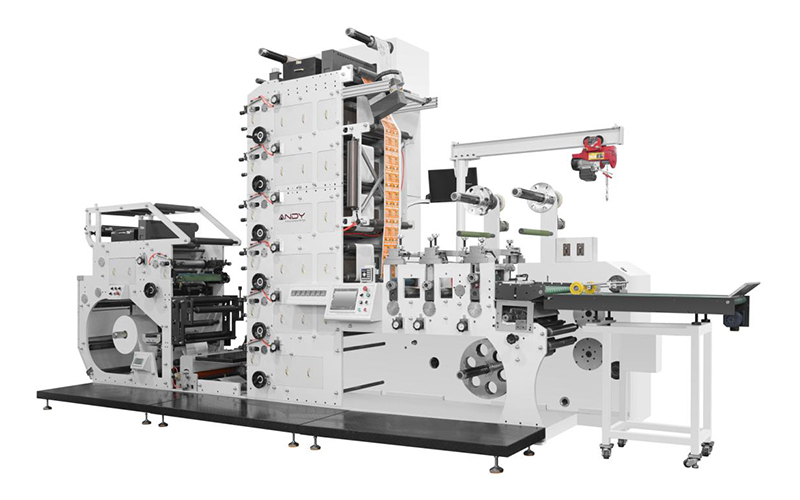

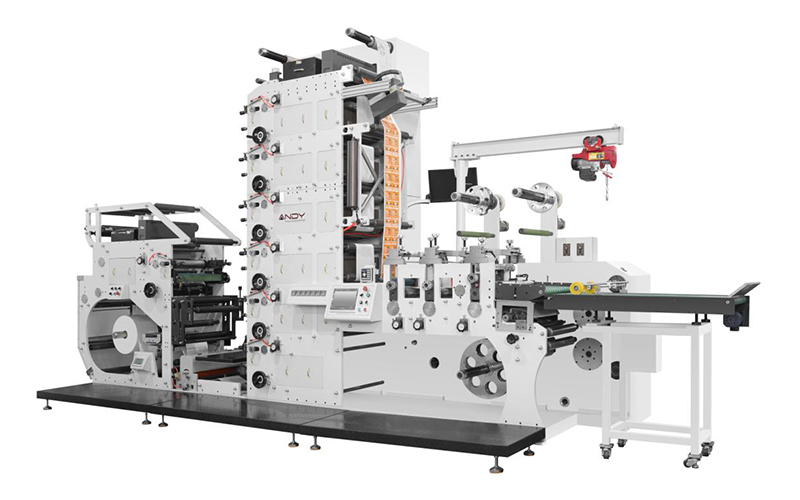

9. The roll feeding, printing, UV vanish, auto infrared drying, laminating and rewinding can be processed in one pass. It has characterized by wide application, fast printing speed and high economic efficiency Ink will not contaminate environment. So it is an idea printing machine for the business form, Tag and high end pressure sensitive label.

10. The inking roller will be automatically off impression when press stop and rotate at lower speed in order to keep the ink from being drying

MAIN

TECHNICAL PARAMETERS:

Model

RY-450

Machine Speed

10-80m/min

Printing Color

2-6Colors

Max. Web Width

450mm

Max. Printing Width

440mm

Max. Unwinding Diameter

600mm

Max. Rewinding Diameter

550mm

Printing Repeat

180-380mm

Thickness of Substrate

0.1-0.3mm

Main Motor Capaticy

2.2KW

Main Power

380V/AC 3 phase 50Hz

Machine Weight

About

2300KGS

Dimensions (L×W×H)

3000×1700×3000mm

VIDEO

Feedback

Welcome to our website. If you have any requests or suggestions,please

feel free to email us at info@andymachinery.com or

use the following enquiry form.